山東軒燁機器人科技有限公司是一家以工業機器人以及自動化非標設備于一體的技術企業,公司致力于焊接、切割、機器人機床上下料等領域的機器人智能化研究和產業化應用

公司立足于高端裝備制造等戰略新興產業,將追逐“制造2025"致力于機器人技術和互聯網技術的深度融合,推動智造。

發布:2024-06-13 瀏覽:0

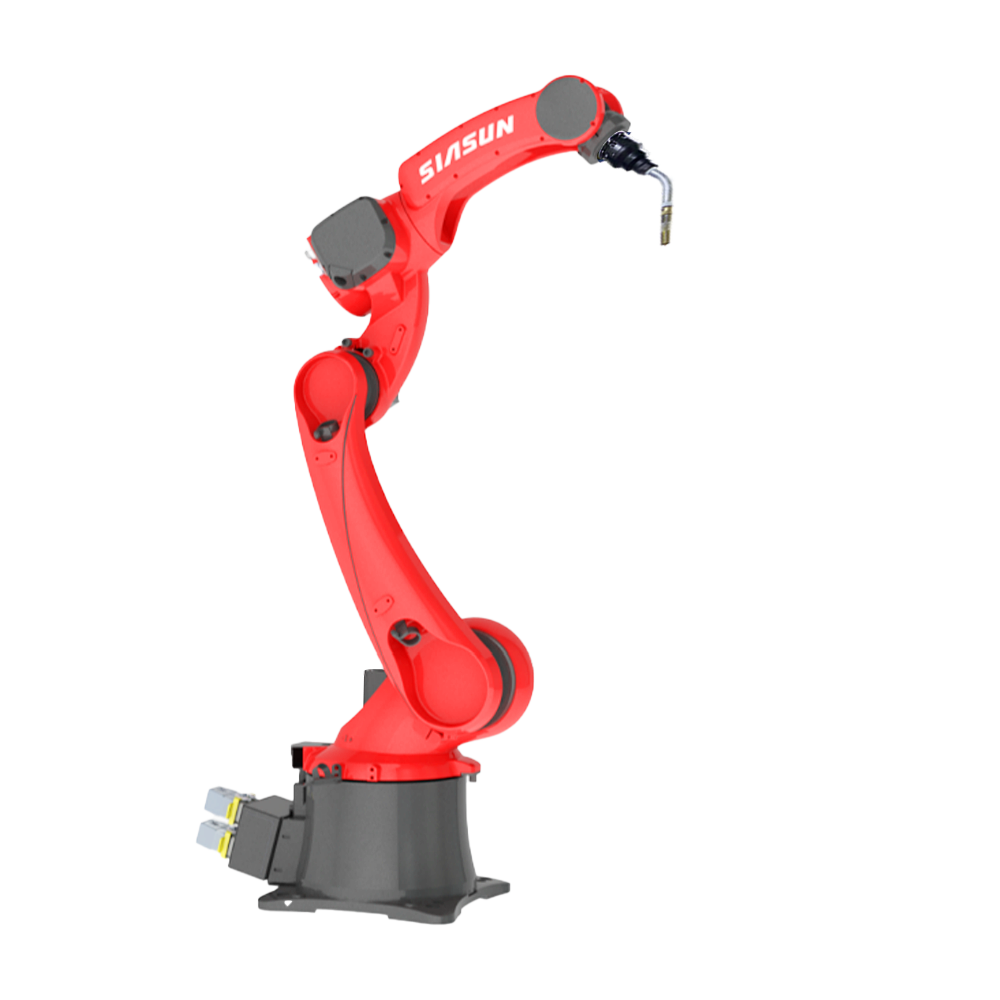

焊接機器人在現代制造業中的應用日益廣泛,特別是在螺母焊接領域,它們通過提高焊接精度和一致性,有效減少焊接缺陷的發生。本文將深入探討焊接機器人在減少螺母焊接缺陷方面的優勢及其背后的原因。

The application of welding robots in modern manufacturing is becoming increasingly widespread, especially in the field of nut welding. They effectively reduce the occurrence of welding defects by improving welding accuracy and consistency. This article will delve into the advantages of welding robots in reducing nut welding defects and the reasons behind them.

焊接機器人的核心優勢

The core advantages of welding robots

焊接機器人通過其高精度和重復性,為螺母焊接提供了革命性的改進。

Welding robots provide revolutionary improvements for nut welding through their high precision and repeatability.

1. 精確的控制

1. Accurate control

焊接機器人能夠精確控制焊接參數,如焊接速度、角度和距離,確保焊縫質量。

Welding robots can accurately control welding parameters, such as welding speed, angle, and distance, to ensure the quality of the weld seam.

2. 重復性和一致性

2. Repeatability and consistency

與手工焊接相比,焊接機器人能夠持續執行相同的操作,保證了焊接過程的重復性和一致性。

Compared with manual welding, welding robots can continuously perform the same operations, ensuring the repeatability and consistency of the welding process.

減少螺母焊接缺陷的原因

Reasons for reducing welding defects in nuts

使用焊接機器人能顯著降低螺母焊接中的缺陷,原因主要包括:

The use of welding robots can significantly reduce defects in nut welding, mainly due to:

1. 減少人為誤差

1. Reduce human error

由于焊接機器人的程序化操作,它能夠減少由人為因素引起的誤差,如手抖或焊接姿勢不當。

Due to the programmatic operation of welding robots, it can reduce errors caused by human factors, such as hand shaking or improper welding posture.

2. 環境適應性

2. Environmental adaptability

焊接機器人能夠在各種環境下穩定工作,即使在極端或不利的環境中也能保持高品質的焊接效果。

Welding robots can work stably in various environments and maintain high-quality welding results even in extreme or unfavorable environments.

3. 實時監控與調整

3. Real time monitoring and adjustment

許多的焊接機器人系統配備了傳感器和視覺系統,能夠實時監控焊接過程并自動調整參數,以應對材料或環境的變化。

Many advanced welding robot systems are equipped with sensors and vision systems, which can monitor the welding process in real time and automatically adjust parameters to cope with changes in materials or environment.

4. 提高生產效率

4. Improve production efficiency

焊接機器人提高了焊接效率,減少了因缺陷而導致的返工和廢品,從而節約成本。

Welding robots improve welding efficiency, reduce rework and waste caused by defects, and thus save costs.

焊接機器人的未來應用前景

Future application prospects of welding robots

隨著技術的不斷進步,焊接機器人將在提高螺母焊接質量方面發揮更大作用。

With the continuous advancement of technology, welding robots will play a greater role in improving the quality of nut welding.

1. 集成更技術

1. Integrate more advanced technologies

未來焊接機器人可能集成更的人工智能和機器學習技術,以進一步優化焊接過程和提高適應性。

Future welding robots may integrate more advanced artificial intelligence and machine learning technologies to further optimize the welding process and improve adaptability.

2. 廣泛應用于各行各業

2. Widely used in various industries

隨著制造業對焊接質量要求的提高,焊接機器人將在更多行業中得到廣泛應用。

With the increasing demand for welding quality in the manufacturing industry, welding robots will be widely used in more industries.

3. 生產線自動化

3. Production line automation

焊接機器人是實現生產線全自動化的關鍵組件,能夠提高整體生產效率和質量控制水平。

Welding robots are key components for achieving full automation of production lines, which can improve overall production efficiency and quality control level.

焊接機器人在制造業的重要性

The importance of welding robots in the manufacturing industry

焊接機器人在減少螺母焊接缺陷方面發揮著關鍵作用,它們不僅提升了焊接質量,還提高了生產效率和性。隨著技術的發展,焊接機器人將繼續成為制造業自動化和創新的重要推動力。

Welding robots play a crucial role in reducing nut welding defects, not only improving welding quality, but also enhancing production efficiency and safety. With the development of technology, welding robots will continue to be an important driving force for manufacturing automation and innovation.

技術發展帶來的新機遇

New opportunities brought by technological development

未來,隨著技術的進一步發展,焊接機器人可能會配備更的傳感器、更強大的計算能力和更精準的控制系統。這些進步將使焊接機器人能夠處理更復雜的任務,并在更廣泛的應用場景中實現精確、的焊接。

In the future, with further technological development, welding robots may be equipped with more advanced sensors, stronger computing power, and more precise control systems. These advancements will enable welding robots to handle more complex tasks and achieve precise and efficient welding in a wider range of application scenarios.

提高生產可持續性

Improving production sustainability

焊接機器人在提高焊接質量和效率的同時,還有助于降低能源消耗還有助于降低能源消耗和材料浪費,推動制造業向更加可持續和的方向發展。

Welding robots not only improve welding quality and efficiency, but also help reduce energy consumption It also helps to reduce energy consumption and material waste, promoting the development of manufacturing towards a more sustainable and environmentally friendly direction.

應對挑戰,拓展應用

Addressing challenges and expanding applications

隨著制造行業面臨的挑戰日益增加,焊接機器人將在提高生產適應性、降低運營成本和應對快速市場變化方面發揮更大作用。它們將成為實現、靈活和可持續生產的關鍵工具。

With the increasing challenges facing the manufacturing industry, welding robots will play a greater role in improving production adaptability, reducing operating costs, and responding to rapid market changes. They will become key tools for achieving efficient, flexible, and sustainable production.

結語:焊接機器人的未來展望

Conclusion: Future prospects of welding robots

焊接機器人正成為推動制造業現代化的關鍵技術。通過持續的技術創新和應用優化,焊接機器人不僅能減少螺母焊接中的缺陷,還將幫助企業實現更高水平的自動化,提升整個行業的生產效率和競爭力。

Welding robots are becoming a key technology driving the modernization of the manufacturing industry. Through continuous technological innovation and application optimization, welding robots can not only reduce defects in nut welding, but also help enterprises achieve higher levels of automation, improve the production efficiency and competitiveness of the entire industry.

本文由 焊接機器人 友情奉獻.更多有關的知識請點擊 http://www.2030588.com 真誠的態度.為您提供為的服務.更多有關的知識我們將會陸續向大家奉獻.敬請期待.

This article is dedicated by welding robots. For more related knowledge, please click on http://www.2030588.com Sincere attitude. We will provide you with comprehensive service. We will gradually contribute more relevant knowledge to everyone. Stay tuned

截屏,微信識別二維碼